The new line of AGS 2000 EN HV introduces the entry-level Agromehanika model for professional farming. Modern design combined with intelligent solutions brings you an innovative machine for plant protection at an affordable price.

The new line of AGS 2000 EN HV introduces the entry-level Agromehanika model for professional farming. Modern design combined with intelligent solutions brings you an innovative machine for plant protection at an affordable price. Users can choose from a range of different manual or hydraulic boom sets. The sprayer features a compact structure that can be customized by installing optional equipment to suit a wide range of different user requirements.

Featuring a sophisticated design, the chassis is made from high-quality materials to ensure a long service life of the sprayer. Adjustable tow-bar enables the connection to the lower or the upper hitch and provides for the accommodation of different attachment fittings. It features an adjustable wheel track, allowing the sprayer to be adapted to specific user requirements. The entire chassis is protected with a modern double-powder coating system.

The chassis features:

Featuring a sophisticated design, the chassis is made from high-quality materials to ensure a long service life of the sprayer. Adjustable tow-bar enables the connection to the lower or the upper hitch and provides for the accommodation of different attachment fittings. It features an adjustable wheel track, allowing the sprayer to be adapted to specific user requirements. The entire chassis is protected with a modern double-powder coating system.

The chassis features:

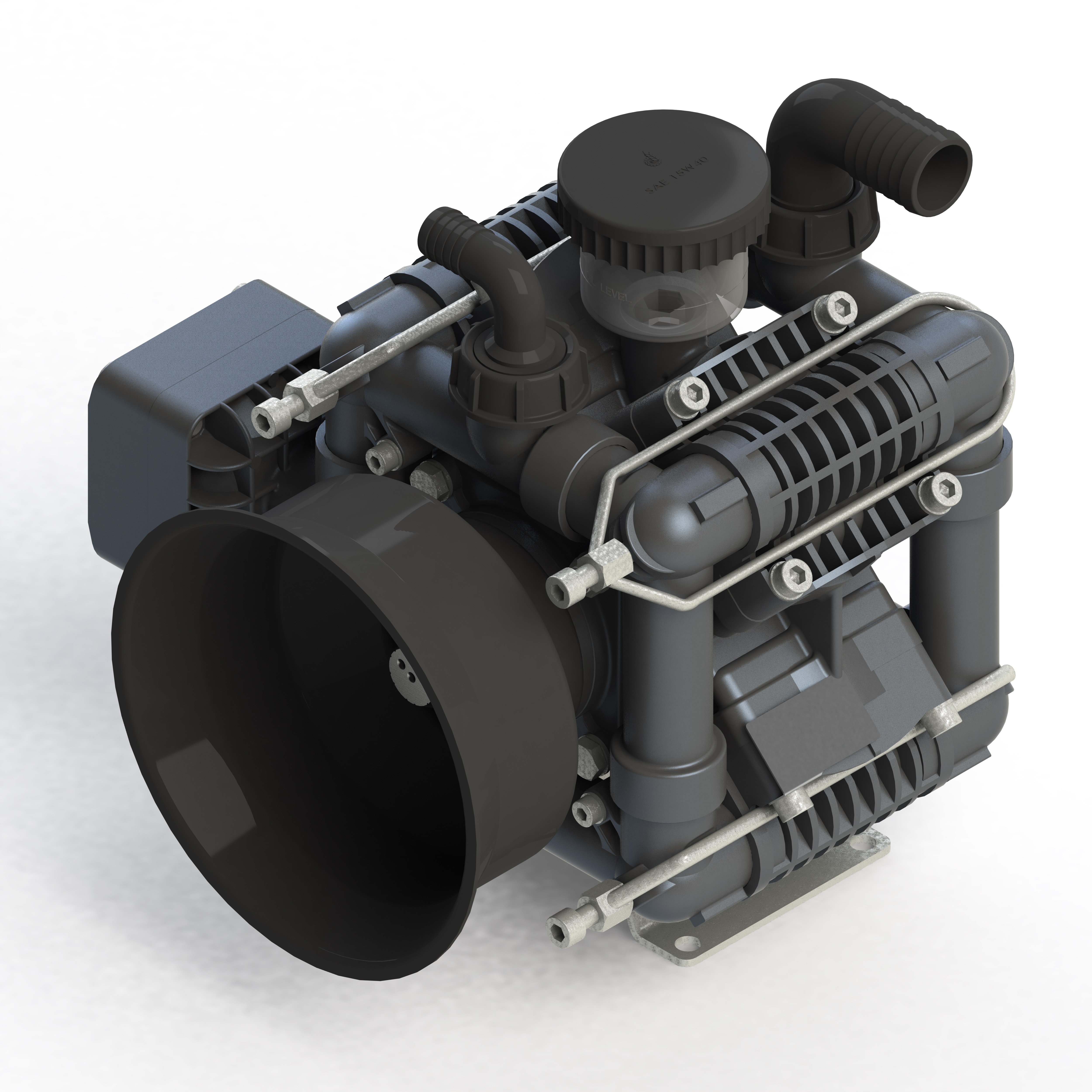

Featuring a 2000 l capacity, its modern design with rounded edges, smooth interior walls and inclined bottom ensures complete drainage and efficient cleaning.

The tank is made of high quality polyethylene, enabling a compact construction and resistance to chemicals.

It is intended for rinsing the main tank and other elements when spraying is finished or interrupted.

The rinsing tank is integrated in the main tank. It can only be filled with clean water. The capacity of the tank is 400 l.

It is designed for washing your hands after handling spraying agents. It can only be filled with clean water. The capacity of the tank is 20 l.

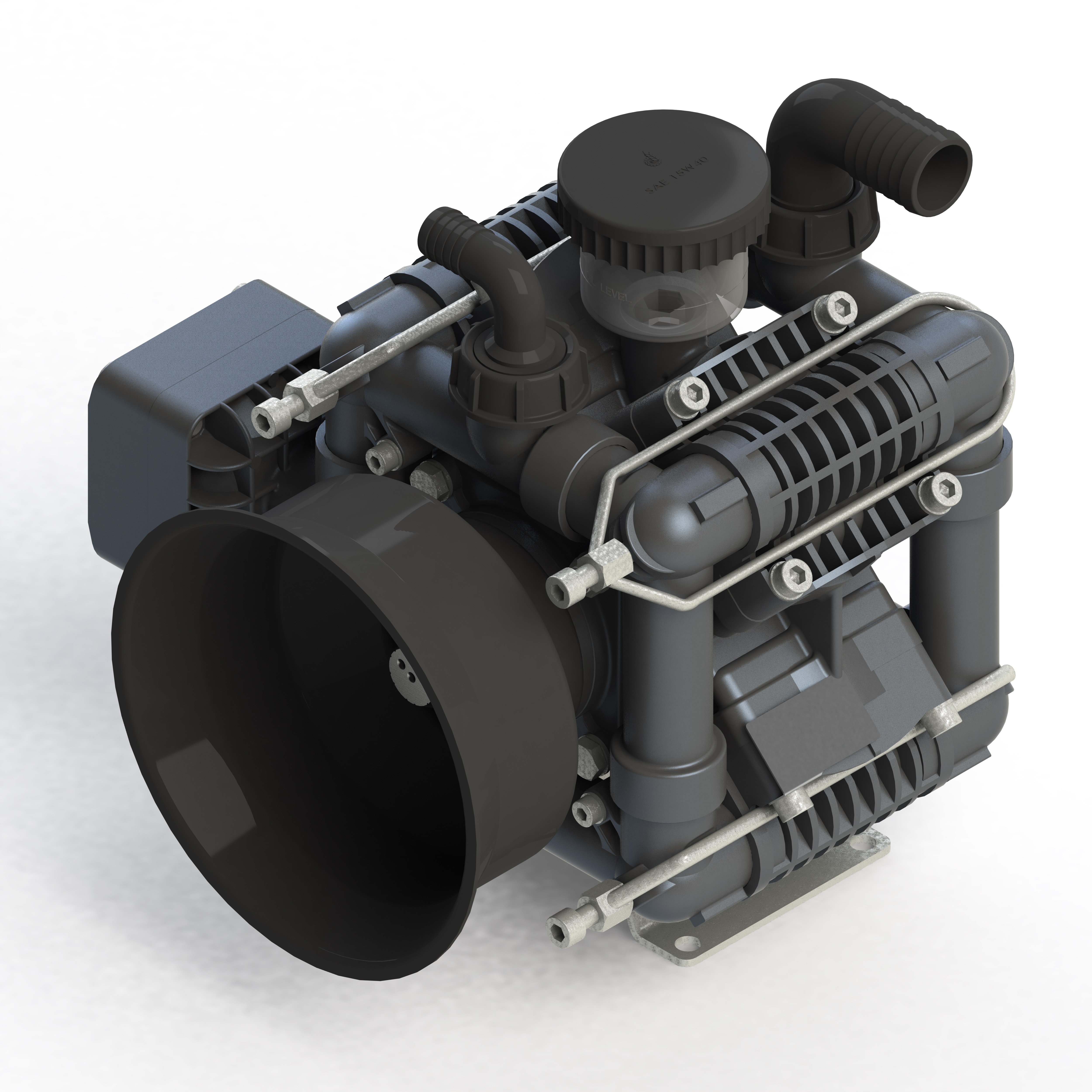

The Agromehanika BM 150/20 pump is a piston diaphragm pump, suitable for pumping liquid sprays and fertilizers. The pump was primarily designed to ensure quality spraying. The pump comes with a 3-year factory warranty.

The Agromehanika BM 150/20 pump is a piston diaphragm pump, suitable for pumping liquid sprays and fertilizers. The pump was primarily designed to ensure quality spraying. The pump comes with a 3-year factory warranty.

The centrifugal mixing pump C 200 with a flow rate of 200 l/min ensures uniform and constant mixing of the spray in the tank.

The mixing pump is connected to the main pump by a V-belt. Mixing is activated only when the PTO drive shaft is engaged

They are designed to mix the spraying agent and prevent the build-up of chemical residues on the bottom of the tank.

The nozzles are actuated by a directional control valve mounted on the regulator. They are installed in the bottom section of the tank. The mixing nozzles are supplied directly by the C 200 centrifugal pump.

It was designed for efficient preparation of chemical products, which is particularly useful for powdered spraying agents that are not readily soluble.

A mixing nozzle and a container rinsing nozzle are both installed inside the filling tank. The capacity of the tank is 30 l.

The sprayer features an external tank filling system for hydrant filling. The system can be used for filling the main tank and the rinsing tank.

The main tank is additionally protected with a non-return valve that prevents the spray from spilling from the tank during filling.

Robust hydraulic boom sets MY-H with working widths of 15, 16 or 18 m ensure reliable and efficient operation at high spraying speeds.

The boom set is hydraulically operated and controlled from the control panel. The control panel is used to control lifting, levelling, locking and simultaneous or individual opening and closing of the left or right boom.

The boom set is mounted on a single-point hitch (eye bearing), enabling an even spray distribution and continuous adjustment of the boom to the terrain conditions in all movement directions. Polyurethane springs are installed to ensure lateral shock absorption and optimal response of the boom set to changing terrain conditions.

It allows simultaneous opening of both sides of the spray boom or individual opening and closing of the left or the right boom. The spray boom set features a safety system to prevent the arms from opening or closing when in working position. The operating speed of hydraulic cylinders is adjustable.

Hydraulic lift system consists of a single-acting hydraulic cylinder. An integrated safety system prevents the spray boom set from suddenly dropping in the event of hose breakage. The operating speed of the hydraulic cylinder is adjustable.

Hydraulic levelling can have a significant impact on even distribution of spray to the surface and, as a result, on the spraying quality. This system is highly recommended for uneven or inclined surfaces as it allows for adjustment of the spray boom set to certain terrain inclinations. The hydraulic cylinder speed can be adjusted.

This system is only used during transport and spraying with partially open boom set (only left or right side). In addition to hydraulic cylinder, the system also features compression springs for additional damping. The operating speed of the hydraulic cylinder is adjustable.

Pneumatic vertical suspension provides additional protection against damages to the spray boom set when spraying at higher speeds or on uneven terrains. The vertical suspension system consists of two air bellows and an inflation valve. The bellows are filled with high-pressure compressed air.

The boom set includes mechanical guards, preventing uncontrolled opening of side arms in the transport position. Transport guards improve the overall manoeuvrability of the sprayer and thus enable higher transport speeds.

The boom arms are designed to protect the nozzles from potential damages (impact with the ground or an unexpected obstacle).

If the sprayer encounters an obstacle, the rear arm moves away and then automatically returns to the original position. The spring sliders prevent the boom set from hitting the ground if the sprayer undergoes sudden movements.

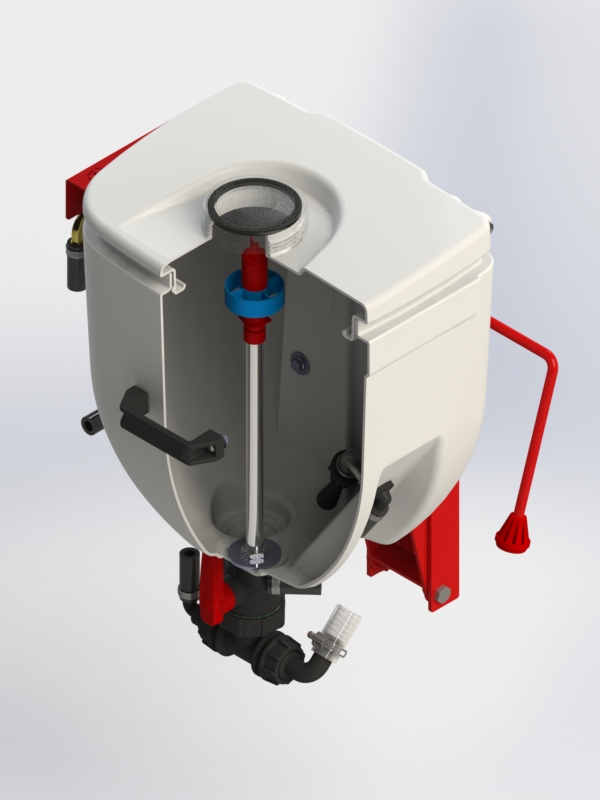

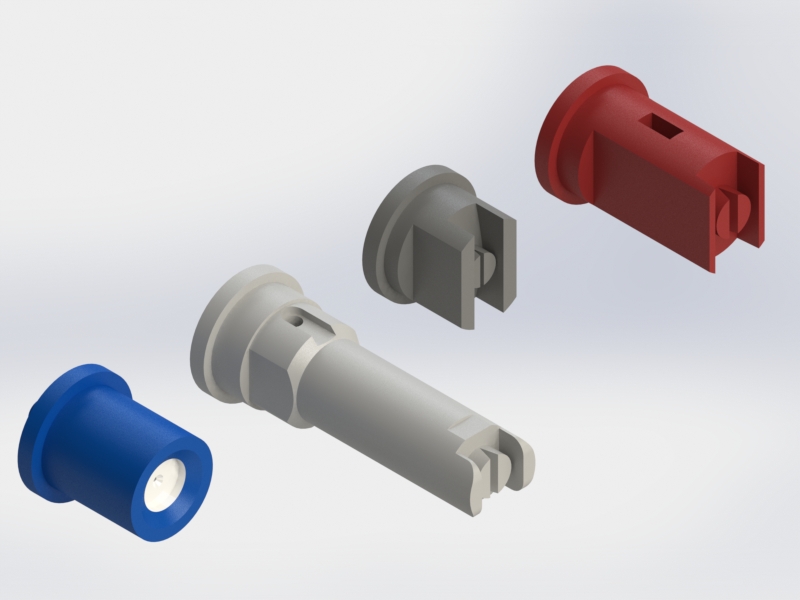

The spray boom sets are fitted with Agromehanika TRI-JET nozzle holders with integrated nozzle inserts by a renowned German manufacturer Lechler. TRI-JET nozzle holders feature three integrated nozzle inserts, designed for spraying different crops. Agromehanika TRI-JET nozzle holders are equipped with an anti-drip diaphragm valve to prevent unwanted dripping from the nozzles.

Robust hydraulic boom sets MY-H with working widths of 15, 16 or 18 m ensure reliable and efficient operation at high spraying speeds.

The boom set is hydraulically operated and controlled from the control panel. The control panel is used to control lifting, levelling, locking and simultaneous or individual opening and closing of the left or right boom.

The boom set is mounted on a single-point hitch (eye bearing), enabling an even spray distribution and continuous adjustment of the boom to the terrain conditions in all movement directions. Polyurethane springs are installed to ensure lateral shock absorption and optimal response of the boom set to changing terrain conditions.

It allows simultaneous opening of both sides of the spray boom or individual opening and closing of the left or the right boom. The spray boom set features a safety system to prevent the arms from opening or closing when in working position. The operating speed of hydraulic cylinders is adjustable.

Hydraulic lift system consists of a single-acting hydraulic cylinder. An integrated safety system prevents the spray boom set from suddenly dropping in the event of hose breakage. The operating speed of the hydraulic cylinder is adjustable.

Hydraulic levelling can have a significant impact on even distribution of spray to the surface and, as a result, on the spraying quality. This system is highly recommended for uneven or inclined surfaces as it allows for adjustment of the spray boom set to certain terrain inclinations. The hydraulic cylinder speed can be adjusted.

This system is only used during transport and spraying with partially open boom set (only left or right side). In addition to hydraulic cylinder, the system also features compression springs for additional damping. The operating speed of the hydraulic cylinder is adjustable.

Pneumatic vertical suspension provides additional protection against damages to the spray boom set when spraying at higher speeds or on uneven terrains. The vertical suspension system consists of two air bellows and an inflation valve. The bellows are filled with high-pressure compressed air.

The boom set includes mechanical guards, preventing uncontrolled opening of side arms in the transport position. Transport guards improve the overall manoeuvrability of the sprayer and thus enable higher transport speeds.

The boom arms are designed to protect the nozzles from potential damages (impact with the ground or an unexpected obstacle).

If the sprayer encounters an obstacle, the rear arm moves away and then automatically returns to the original position. The spring sliders prevent the boom set from hitting the ground if the sprayer undergoes sudden movements.

The spray boom sets are fitted with Agromehanika TRI-JET nozzle holders with integrated nozzle inserts by a renowned German manufacturer Lechler. TRI-JET nozzle holders feature three integrated nozzle inserts, designed for spraying different crops. Agromehanika TRI-JET nozzle holders are equipped with an anti-drip diaphragm valve to prevent unwanted dripping from the nozzles.

The HLX fully hydraulic boom set with a working width of 15 m offers reliable and efficient operation at normal working speeds. The operator is able to control the lift, terrain following and opening of the boom set from the tractor cab. The boom set can be opened partially on one side or simultaneously on both sides.

The boom set is hydraulically operated and controlled from the control panel. The control panel is used to control lifting, levelling and individual opening and closing of the left or right boom, as well as simultaneous opening of the boom set.

It allows individual opening and closing of the left or the right boom. The spray boom set features a safety system to prevent the arms from opening or closing when in working position. The operating speed of hydraulic cylinders is adjustable.

All AGS 2000 EN HV sprayers feature hydraulic lift system, consisting of a single-acting hydraulic cylinder. An integrated safety system prevents the spray boom set from suddenly dropping in the event of hose breakage. The operating speed of the hydraulic cylinder is adjustable. Our customers can choose from various options for vertical suspension of the boom set.

Hydraulic levelling can have a significant impact on even distribution of spray to the surface and, as a result, on the spraying quality. This system is highly recommended for uneven or inclined surfaces as it allows for adjustment of the spray boom set to certain terrain inclinations. The hydraulic cylinder speed can be adjusted.

This boom set is distinguished by an automatic lock that activates when the booms are closed. The lock helps prevent damage to the boom set during transport.

The boom set includes mechanical guards, preventing uncontrolled opening of side arms in the transport position. Transport guards improve the overall manoeuvrability of the sprayer and thus enable higher transport speeds.

The boom arms are designed to protect the nozzles from potential damages (impact with the ground or an unexpected obstacle).

If the sprayer encounters an obstacle, the rear arm moves away and then automatically returns to the original position. The spring sliders prevent the boom set from hitting the ground if the sprayer undergoes sudden movements.

The spray boom sets are fitted with Agromehanika TRI-JET nozzle holders with integrated nozzle inserts by a renowned German manufacturer Lechler. TRI-JET nozzle holders feature three integrated nozzle inserts, designed for spraying different crops. Agromehanika TRI-JET nozzle holders are equipped with an anti-drip diaphragm valve to prevent unwanted dripping from the nozzles.

The MY-H fully hydraulic boom set with a working width of 12 m offers reliable and efficient operation at normal working speeds. The operator is able to control the lift, terrain following and opening of the boom set from the tractor cab.

The boom set is hydraulically operated and controlled from the control panel. The control panel is used to control lifting, levelling and simultaneous or individual opening and closing of the left or right boom.

This system enables the boom set to follow the terrain automatically (±10° slope). The integrated lateral oscillation stabiliser prevents damage to the boom set structure.

It allows simultaneous opening of both sides of the spray boom or individual opening and closing of the left or the right boom. The spray boom set features a safety system to prevent the arms from opening or closing when in working position. The operating speed of hydraulic cylinders is adjustable.

All AGS 2000 EN HV sprayers feature hydraulic lift system, consisting of a single-acting hydraulic cylinder. An integrated safety system prevents the spray boom set from suddenly dropping in the event of hose breakage. The operating speed of the hydraulic cylinder is adjustable. Our customers can choose from various options for vertical suspension of the boom set.

Hydraulic levelling can have a significant impact on even distribution of spray to the surface and, as a result, on the spraying quality. This system is highly recommended for uneven or inclined surfaces as it allows for adjustment of the spray boom set to certain terrain inclinations. The hydraulic cylinder speed can be adjusted.

This boom set is distinguished by an automatic lock that activates when the booms are closed. The lock helps prevent damage to the boom set during transport.

The boom set includes mechanical guards, preventing uncontrolled opening of side arms in the transport position. Transport guards improve the overall manoeuvrability of the sprayer and thus enable higher transport speeds.

The boom arms are designed to protect the nozzles from potential damages (impact with the ground or an unexpected obstacle).

If the sprayer encounters an obstacle, the rear arm moves away and then automatically returns to the original position. The spring sliders prevent the boom set from hitting the ground if the sprayer undergoes sudden movements.

The spray boom sets are fitted with Agromehanika TRI-JET nozzle holders with integrated nozzle inserts by a renowned German manufacturer Lechler. TRI-JET nozzle holders feature three integrated nozzle inserts, designed for spraying different crops. Agromehanika TRI-JET nozzle holders are equipped with an anti-drip diaphragm valve to prevent unwanted dripping from the nozzles.

As standard, the 12 m MY boom set features hydraulic opening. The boom set provides a high degree of reliability and efficiency at normal working speeds.

It enables opening and closing of the spray boom set. The spray boom set features a safety system to prevent the arms from opening or closing when in working position. The operating speed of hydraulic cylinders is adjustable.

This system enables the boom set to follow the terrain automatically (±10° slope). The integrated lateral oscillation stabiliser prevents damage to the boom set structure.

This boom set is distinguished by an automatic lock that activates when the booms are closed. The lock helps prevent damage to the boom set during transport.

The boom set includes mechanical guards, preventing uncontrolled opening of side arms in the transport position. Transport guards improve the overall manoeuvrability of the sprayer and thus enable higher transport speeds.

The boom arms are designed to protect the nozzles from potential damages (impact with the ground or an unexpected obstacle).

If the sprayer encounters an obstacle, the rear arm moves away and then automatically returns to the original position. The spring sliders prevent the boom set from hitting the ground if the sprayer undergoes sudden movements.

As standard, the AGS 1500 EN trailed sprayers are equipped with hydraulic lift system consisting of a single-acting hydraulic cylinder. An integrated safety system prevents the spray boom set from suddenly dropping in the event of hose breakage. The operating speed of the hydraulic cylinder is adjustable.

The spray boom sets are fitted with Agromehanika TRI-JET nozzle holders with integrated nozzle inserts by a renowned German manufacturer Lechler. TRI-JET nozzle holders feature three integrated nozzle inserts, designed for spraying different crops. TRI-JET Agromehanika nozzle holders are equipped with an anti-drip diaphragm valve to prevent unwanted dripping from the nozzles.

MRX (12 and 15 m) mechanical boom sets are characterized by their light and resilient structure. They can be upgraded with hydraulic lift system and hydraulic terrain following. The main competitive advantages of MRX boom sets are robust design and longer service life.

This system enables the boom set to follow the terrain automatically (±10° slope). The integrated lateral oscillation stabiliser prevents damage to the boom set structure.

As standard, the AGS 1500 EN trailed sprayers are equipped with hydraulic lift system consisting of a single-acting hydraulic cylinder. An integrated safety system prevents the spray boom set from suddenly dropping in the event of hose breakage. The operating speed of the hydraulic cylinder is adjustable.

The boom set can be opened and closed simply and quickly. A wire rope with adjustable tension ensures proper stability of the boom set during operation.

MRX spray boom sets feature two mechanical locks:

four-point trapezoid hitch lock,

unintentional boom set opening lock.

The boom arms are designed to protect the nozzles from potential damages (impact with the ground or an unexpected obstacle).

If the sprayer encounters an obstacle, the rear arm moves away and then automatically returns to the original position.

MRX boom sets can be optionally equipped with spring sliders that prevent the boom set from hitting the ground during violent motion. These spring sliders are integrated in the boom set as standard equipment.

The spray boom sets feature Agromehanika TRI-JET nozzle holders with integrated nozzle inserts by a renowned German manufacturer Lechler. The nozzle holders feature three integrated nozzle inserts, designed for spraying different crops. These nozzle holders are also equipped with an anti-drip diaphragm valve to prevent unwanted dripping from the nozzles.

For safe driving on public roads.

The sprayer is equipped with two reflective boards, rear lights with a reflective triangle and two white reflectors installed on the boom set.

Thanks to the control panel, the boom set can be controlled from the tractor cab. It is operated by tractor hydraulics.

The hydraulic system is used to control lifting, levelling or terrain following and simultaneous or individual opening of the left or the right boom.

Thanks to the control panel, the boom set can be controlled from the tractor cab. It is operated by tractor hydraulics.

The hydraulic system is used to control lifting, levelling or terrain following and simultaneous or individual opening of the left or the right boom.

AG-TRONIK is a modern computer manufactured by Agromehanika, which is used for monitoring and automatic adjustment of spray volume per hectare. It makes the spraying process easier, more accurate and more efficient.

Partial cleaning of the sprayer does not affect the spray content in the main tank.

Such cleaning is very useful if spraying is interrupted for various reasons (lack of time, weather conditions etc.).

Partial cleaning includes cleaning the suction filter, the pump, the pressure regulator and nozzles. The sprayer can be easily adjusted for partial cleaning. Clean water is pumped from the rinsing tank by means of a pump. It is recommended to clean the machine after each use.

Partial cleaning of the sprayer does not affect the spray content in the main tank.

Such cleaning is very useful if spraying is interrupted for various reasons (lack of time, weather conditions etc.).

Partial cleaning includes cleaning the suction filter, the pump, the pressure regulator and nozzles. The sprayer can be easily adjusted for partial cleaning. Clean water is pumped from the rinsing tank by means of a pump. It is recommended to clean the machine after each use.

The sprayer should be fully cleaned after each spraying. This contributes to cost-effective spraying and environmental protection.

It removes all spray residues from the sprayer. Full cleaning includes the cleaning of all interior parts of the sprayer, consisting of the main tank, the suction filter, the pump, the pressure regulator and the nozzles. The sprayer is easily adjusted for full cleaning. Clean water is pumped from the rinsing tank by means of a pump.

The suction filter is used for spray filtration. In addition, it also removes larger particles from the spray that could cause problems during spraying.

The suction filter is installed between the main tank and the pump. The filter insert features a density of 50 MESH. It is recommended to clean the suction filter before each filling of the main tank.

The self-cleaning pressure filter provides additional filtration of the spray before it enters the nozzles and allows uninterrupted spraying.

It is located on the sprayer's pressure regulator.

The filter insert features a density of 50 MESH.

The pressure filter should be thoroughly cleaned after spraying.

The nozzles are designed for cleaning the interior surface of the main tank after spraying. They further remove any spray residues, thus contributing to cost-effective spraying and environmental protection.

The nozzles are installed inside the main tank. They are actuated by a directional control valve mounted on the regulator. Clean water is pumped from the rinsing tank.

In combination with AG-TRONIK spraying computer, the G7 Farmnavigator navigation system ensures controlled and accurate spraying, while the user can entirely focus on driving. It saves time and spray costs.

THE GPS NAVIGATION SYSTEM DETECTS:

THE GPS NAVIGATION SYSTEM ENABLES:

9.5−42 wheels are taller and wider than standard 9.5−36 wheels. This enables spraying at greater heights and higher ground clearance.

The German manufacturer Lechler ranks among the Europe's leading manufacturer of nozzles for agricultural applications. The Lechler nozzles follow the latest trends in agriculture, enabling efficient and accurate spraying.

A wide range of available nozzles according to plant varieties, materials and standards. Modern nozzles for reducing spray drift (off-target spray diffusion). Lechler products have been tested and certified by the German Federal Research Centre for Cultivated Plants JKI (www.jki.bund.de).

The suction basket is designed for pumping water from ponds, streams and wells. Water is pumped into the main tank through the filter, the pump and the regulator. The suction basket is easily attached using the bayonet fitting under the main tank.

We recommend cleaning the exterior of the machine after each spraying. This ensures uninterrupted operation of the machine by removing the residues of the aggressive chemicals.

Cleaning should be performed at the edge of the area that was sprayed. The kit includes a spraying lance and a hose with a connection fitting. The kit is attached to one of the valves mounted on the regulator.

The foam marker is used to mark the boundaries of surfaces that have already been treated. This enables the operator to identify and distinguish between treated and untreated areas.

Foam balls with a diameter of 10 to 20 cm form a line that marks the edge of the treated area. Depending on the marker's adjustment, the border is marked every 5–20 seconds.