The filling container is usually located at an easily accessible place that enables control over the operation of the sprayer. It provides a controlled environment for the preparation of the spray mixture in a way that reduces the risks for the operator to a minimum. It is important to minimize the duration of the user's exposure because the concentration of chemical products is the highest when they are mixed with water, causing the highest risk for the user.

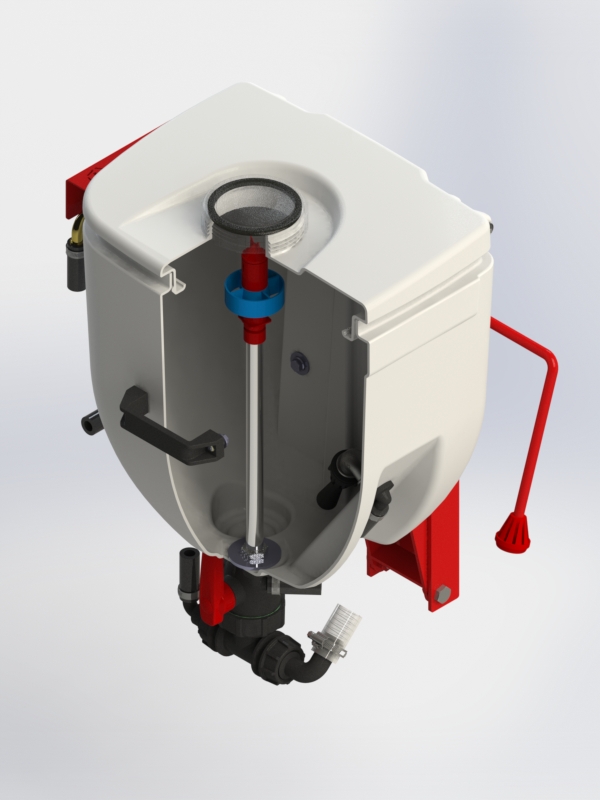

A quality filling container provides complete control to the user and is easy to handle. One of the key features of a filling container is the height of its attachment. The latter must not be too high, particularly as this would complicate the dosage of powder-based chemical products in bags. Modern filling containers also provide the option of trapezoid attachment, which enables lowering the filling container with a lever to facilitate the delivery of chemical products in the container. This also means that the container is at a greater distance from the user, which reduces the risk of spray drifting into the user's eyes and mouth. Thanks to the mixing nozzle, the chemical product completely dissolves inside the filling container. A completely dissolved spray mixture enables greater efficiency of application and a more even distribution, and there is also less unnecessary residue. A filling container also prevents the foam from leaking out of the sprayer during the filling process, which is common when the chemical product is delivered through the strainer at the top of the sprayer, thus protecting the user and reducing the negative environmental impact. Modern filling containers also enable complete washing of packaging of chemical products to significantly reduce the unwanted spray drift outside the area which is being treated, in addition to reducing the adverse effects for the user and the environment.

When designing sprayers, Agromehanika places a strong emphasis on user safety. When modern filling stations were first introduced several years ago, they were only fitted on our largest trailed sprayers, but today they are integrated as standard sprayer equipment in all white-line sprayers with a capacity of 800 litres or more and they are, of course, also available as optional equipment for smaller models. Find out more about standard and optional sprayer equipment on the following link.